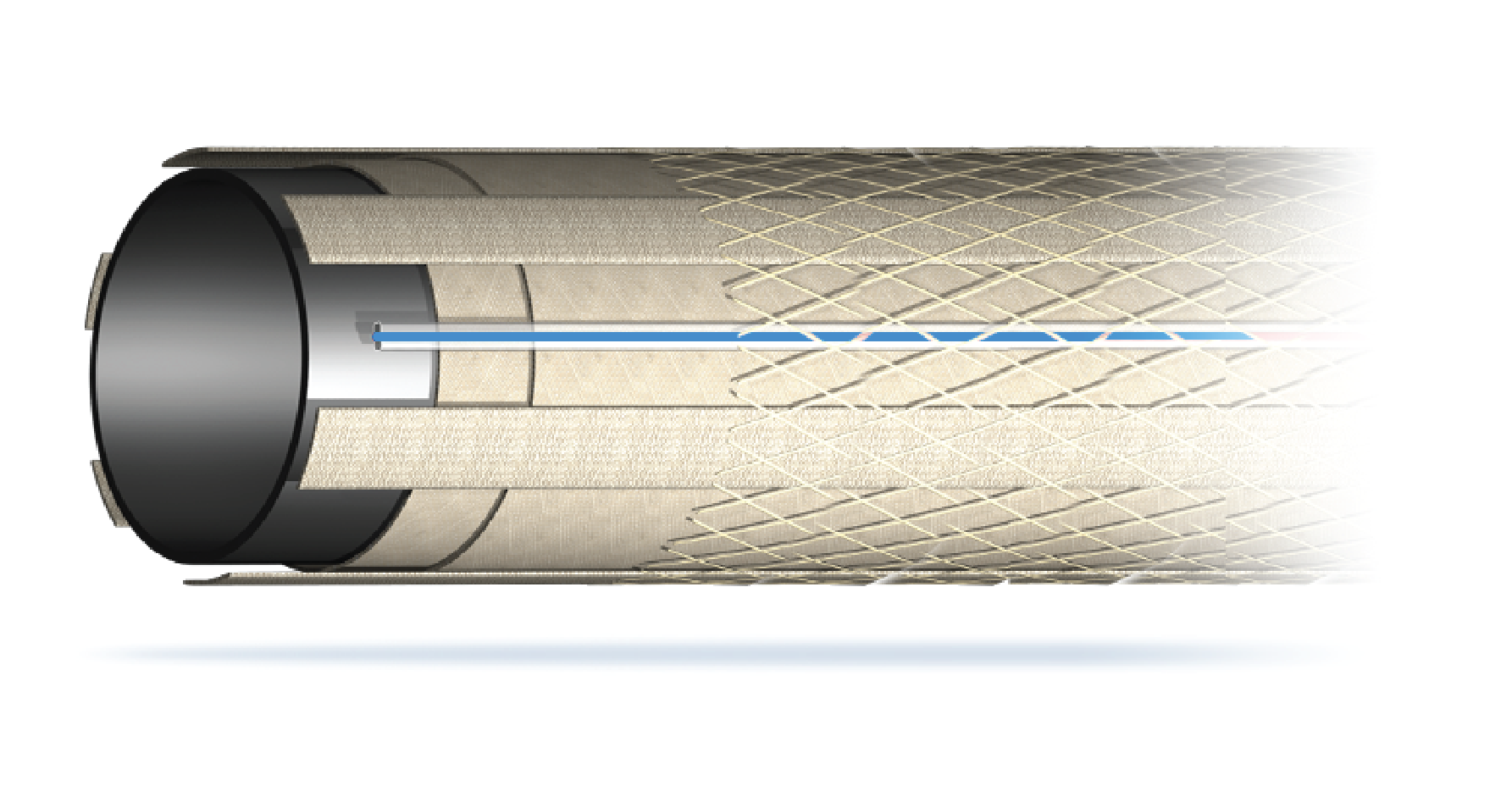

Smartpipe® is a high-pressure reinforced thermoplastic pipeline replacement technology.

![]()

Today’s operators are continually facing increasing challenges associated with the safe operation of their aging pipeline infrastructure as well as the increasingly difficult prospect of the construction of new pipelines anywhere in the world.

As environmental, social, and governance factors influence company decisions, Smartpipe® is ideally positioned to meet these demands. Designed according to API 15S and ASTM Standard F2896-11, it is a non-invasive, trenchless technology that allows operators access to difficult areas, can restore the operation of nonfunctional pipelines, and even allows for change of service on existing pipelines, all while continuously monitoring through the use of fiber optic sensing technology.

Using our patented technology, we install on-site through a host pipeline or as a standalone pipeline, minimizing the need for the entire right of way disturbance and greatly reducing the amount of preparation time and permits.

Non-Invasive Pipeline Replacement

No Dig, Trenchless Technology

Access Difficult Areas

Several Miles in One

Continuous Pull

Make Informed Decisions

Embedded Fiber Optic Monitoring & Communications

The Smartpipe® Advantage

New Life for Aging Pipelines

![]()

Large Diameter

![]()

Large Diameter

Smartpipe® can be custom manufactured to a range of diameters to be designed as a “close fit” inside a host pipeline for maximizing product flow capacity. As an alternative, a smaller diameter Smartpipe® (i.e. 12″) can be inserted in a larger diameter host steel pipeline (i.e. 20″), thus adapting the existing pipeline to current flow and product requirements.

High Pressure

![]()

High Pressure

The Smartpipe® system is currently designed with safety factors approximately 3x greater than those for steel pipelines. Smartpipe® can be utilized within a degraded steel host pipeline, returning the system to or exceeding the original pipeline pressure rating.

Long Pull Lengths

![]()

Long Pull Lengths

High-strength pulling tapes are laid longitudinally along the Smartpipe®system, allowing a pull of several miles through a host steel pipeline. This unique advantage is achieved by the use of our mobile assembly plant, allowing continuous Smartpipe® production on-site.

Fiber Optic Monitoring

Fiber Optic Monitoring

Smartpipe®embedded fiber optic monitoring and communication system gives the pipeline operator real-time information on potential threats. The 24/7 monitoring is accurate to approximately one meter and can identify leaks and any pipeline movement, including any third-party intrusion—the most common cause of pipeline incidents.

Large Diameter

![]()

Large Diameter

Smartpipe® can be custom manufactured to a range of diameters to be designed as a “close fit” inside a host pipeline for maximizing product flow capacity. As an alternative, a smaller diameter Smartpipe® (i.e. 12″) can be inserted in a larger diameter host steel pipeline (i.e. 20″), thus adapting the existing pipeline to current flow and product requirements.

High Pressure

![]()

High Pressure

The Smartpipe® system is currently designed with safety factors approximately 3x greater than those for steel pipelines. Smartpipe® can be utilized within a degraded steel host pipeline, returning the system to or exceeding the original pipeline pressure rating.

Long Pull Lengths

![]()

Long Pull Lengths

High-strength pulling tapes are laid longitudinally along the Smartpipe® system, allowing a pull of several miles through a host steel pipeline. This unique advantage is achieved by the use of our mobile assembly plant, allowing continuous Smartpipe® production on-site.

Faster Project Completion With 70% Lower Carbon Footprint

Faster Project Completion With 70% Lower Carbon Footprint

Smartpipe® can be manufactured and installed at a rate of approximately 1 mile per day. Also, due to the minimal disruption of right of way, the permitting and preparation period is shortened.

Used With Host or Standalone Pipeline

![]()

Used With Host or Standalone Pipeline

Smartpipe® is a non-intrusive trenchless pipeline replacement technology. We use the existing pipeline infrastructure to bring a new generation of pipeline. Even though we are predominately inserted into an existing pipeline, Smartpipe® is designed and can be laid as a fully structural, high-pressure stand-alone pipeline.

Repurpose Existing Pipelines

![]()

Repurpose Existing Pipelines

Smartpipe® reinforced thermoplastic pipe allows for a change in service in existing pipelines.

Hydrogen Piping Standard B31.12, Code Case 200

Smartpipe® has been tested by the U.S. Department of Energy’s Savannah River National Laboratories as described and illustrated in the latest Hydrogen Piping Standard B31.12, Code Case 200.

Meeting ESG Goals

There has been a major shift towards accomplishing Environmental, Social, Governance initiatives in all industries. Smartpipe® offers a unique opportunity to accomplish ESG goals. With no distribution to the environment, and providing a feasible entry into the energy transition, Smartpipe® provides innovative solutions geared towards improving your company’s ESG score.

Introducing The SQUIID®

The World’s First ILI Tool for Composite Pipelines

![]()

Self-monitoring

Self-Monitoring

Smartpipe®embedded fiber optic monitoring and communication system, together with our patented SQUIID® ILI system, make Smartpipe® the SAFEST and BEST AVAILABLE TECHNOLOGY today.

High Pressure

![]()

High Pressure

The Smartpipe® system is currently designed with safety factors approximately 3x greater than those for steel pipelines.

Long Pull Lengths

![]()

Long Pull Lengths

High-strength pulling tapes are laid along the Smartpipe®system, allowing a pull of several miles through a host steel pipeline.

Contact Us

![]()

Visit Us

![]()

Privacy Policy & Terms and Conditions | Designed by ADV Marketing